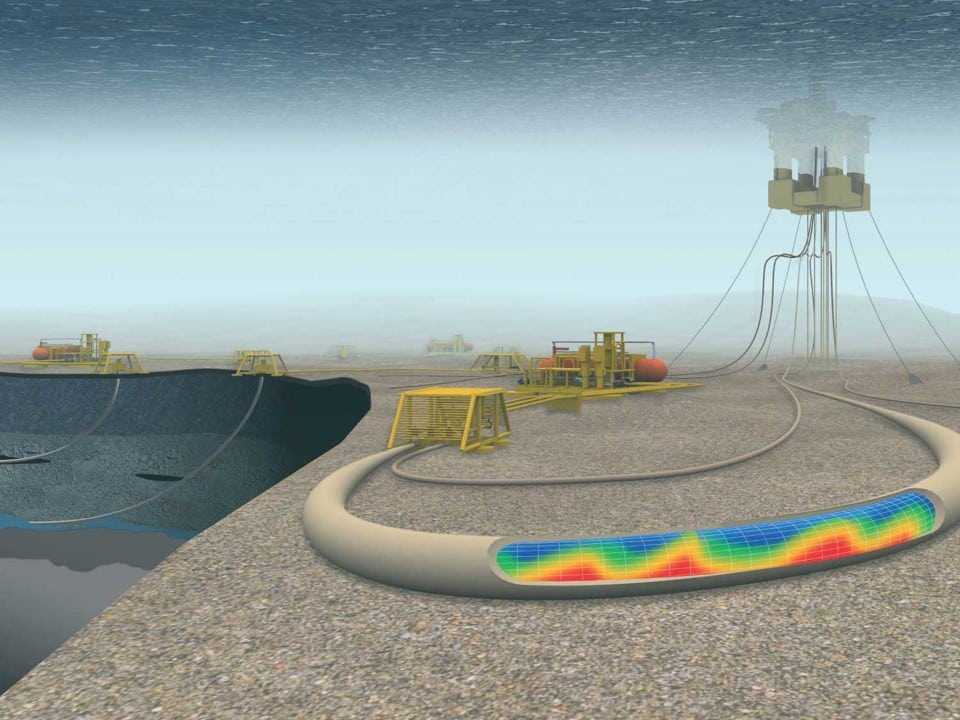

LedaFlow® is the product of many years of innovative development by SINTEF, sponsored, guided and supported by TotalEnergies and ConocoPhillips, commercialized and developed further by KONGSBERG.

The history of LedaFlow® started in 2001. Acknowledging the need for a new multiphase simulation tool, ConocoPhillips teamed up with SINTEF to launch a research and development project dedicated to the transport of multiphase flow in pipelines. After initial ideas for models and experiments were discussed, TotalEnergies was invited to join the project which received the name LedaFlow in 2002.

The objective of the LedaFlow project was as follows: “To develop a new dynamic simulator for multiphase flow assurance analysis, design and support for oil and gas operations.”

A set of full-scale experiments were carried out in the SINTEF Multiphase Flow Laboratory in Tiller. These initial experiments, conducted on the Large-Scale Loop, allowed to gather high-quality data on two-phase flow in 8″ and 12″ pipes.

This data entered the Tiller database, which gathers data from the various R&D programs performed at SINTEF over the last decades. The Tiller database was used to demonstrate the performance of the LedaFlow models and its scaling capabilities.

Based on these results, the LedaFlow technology concept was proved in 2004.

The following years focused on the development of the engineering tool. New experiments were conducted in the Large Scale Loop of the SINTEF Multiphase Flow Laboratory. TotalEnergies and ConocoPhillips contributed actively to the validation of the LedaFlow models. Each partner used their own field and well data to verify the accuracy and quality of the simulation results.

In addition to robustness and accuracy a lot of attention was brought on the usability of LedaFlow. A LedaFlow Technology Forum was established in 2009 in order to promote end user feedback and to ensure that the LedaFlow® effectively fulfil industrial needs and standards. The involvement of five major oil companies (Shell, Saudi Aramco, ENI, Chevron and Statoil) in the Technology Forum also contributed to validate the LedaFlow models with new field data.

As the LedaFlow engineering tool started to take shape, SINTEF, TotalEnergies and ConocoPhillips started working on its introduction to the market and, in 2008, KONGSBERG was selected as the commercialization partner.

A Customer Acceptance Test (CAT) was conducted in 2010 by the LedaFlow partners. For three months, LedaFlow was extensively tested using a large number of experimental databases and field data. The success of the CAT marked the end of the second phase of the research and development project and the beginning of the commercialization project of LedaFlow.

The first commercial version of LedaFlow® (1.0) was released in June 2011.

Since then, LedaFlow® has continued to improve, benefiting from fast-paced R&D and the implementation of new important features. New versions are regularly released to make those improvements available to LedaFlow® users.

LedaFlow Technologies DA is a company established in 2013 by the four LedaFlow partners, ConocoPhillips, TotalEnergies, SINTEF and Kongsberg Digital. LTDA’s mission is to utilize the expertise of the four partners to ensure a continuous development of the LedaFlow products and bring to the industry the best available tool for multiphase flow simulation.

LIFT (LedaFlow Improvements to Flow Technology) is a 3-year joint industry project that was first established in 2013. The purpose of LIFT is to let its participants support and influence the improvements

and qualification of the transient multiphase simulator technology that is offered via the LedaFlow Engineering tool. Read more about the achievements of the successive LIFT projects.

Several R&D projects are conducted to improve the LedaFlow models for the oil and gas industry.

– Cost effective management of hydrates and wax with LedaFlow® (2016-2019)

– ACCURATE (2017-2020)

– Chemflow (2020-2024)

A considerable effort is also brought on the speed improvement of LedaFlow. Through several R&D projects, a new numerical solver has been developed, demonstrated and released commercially. It allows faster Slug Capturing simulations and better parallelization.

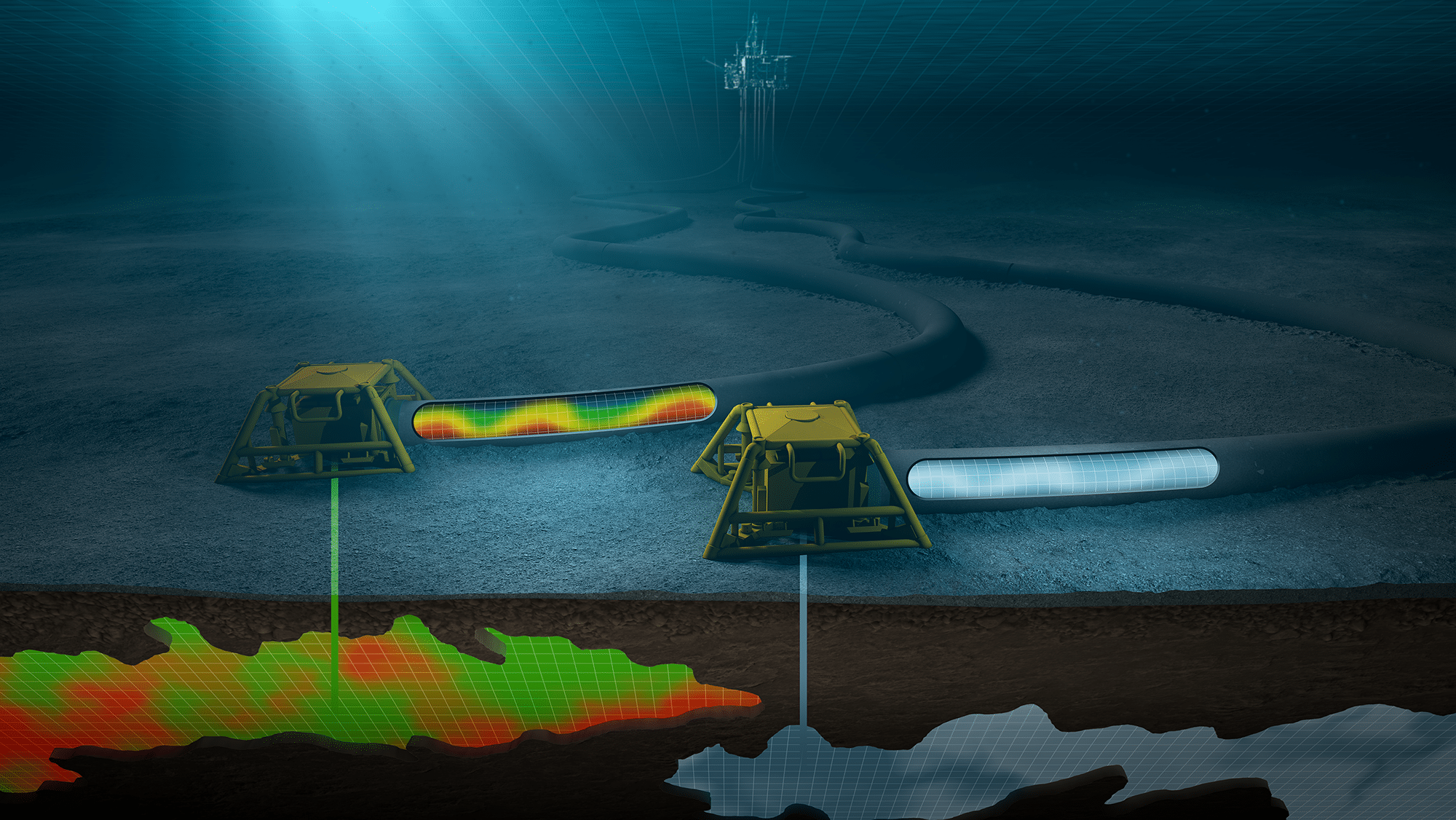

In 2018 LTDA joined CO2FACT, a JIP created by Equinor, TotalEnergies and Shell. Numerous CO2 experiments were conducted at IFE Kjeller, creating a foundation for benchmarking, tuning and further development of CO2 capabilities in multiphase flow simulators like LedaFlow. One of the purposes was to quantify and reduce simulations uncertainty for the design and operation of CO2 systems.

LedaFlow Technologies DA has been executing the CLIMIT innovation project “CO2Flow – Advancing LedaFlow for robust and accurate multiphase flow simulations to enable transport and injection of CO2”.

The project was originally set up with 4 energy companies and a duration of 3 years. However, both the scope and project size has grown as 3 additional participants decided to join the project. This project started in 2022 and is scheduled to complete in spring 2026. The extension of the project was possible thanks to industrial funding.

The project works on accuracies for pure CO2 and CO2 with impurities to improve the models in LedaFlow and deliver an accurate CO2 simulator.

Kongsberg Digital is managing the CLIMIT demo project “GELECO2, Development of integrated software for running the multiphase simulator LedaFlow with the reservoir simulator GEM for simulating multiphase CO2 injection flow between well and reservoir”.

The project was received with a great interest by the industry and a total of 13 companies joined it in addition to Kongsberg Digital and CMG.

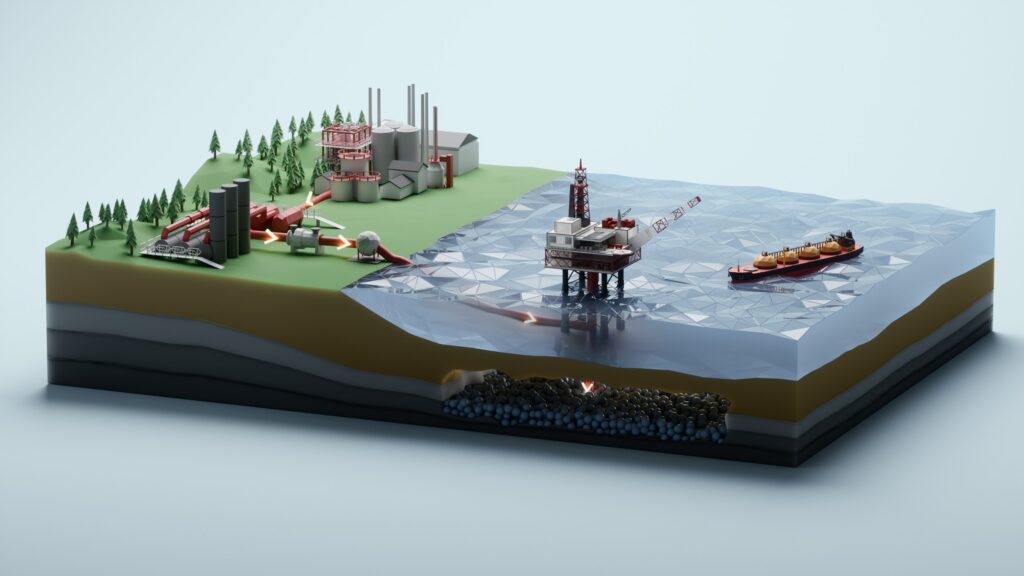

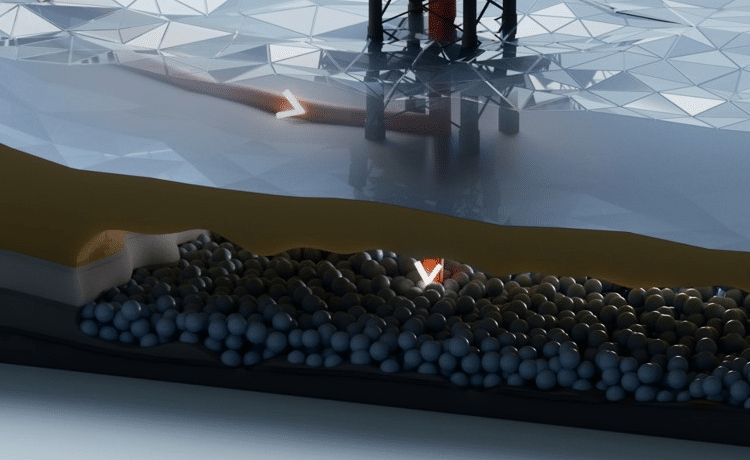

Today LedaFlow® holds a set of unique technology for doing all types of flow assurance studies including hydrodynamic slug prediction, wax deposition, hydrate transport, hydrogen transport and CO2 transport. It is also extensively used for well performance studies.

You may find interesting papers of successful applications in our bibliography.

The LedaFlow® suite of products includes the LedaFlow® Point Model, LedaFlow® Engineering, LedaFlow Slug Capturing and LedaFlow® Integrated.

Fueled by BENZIN AS