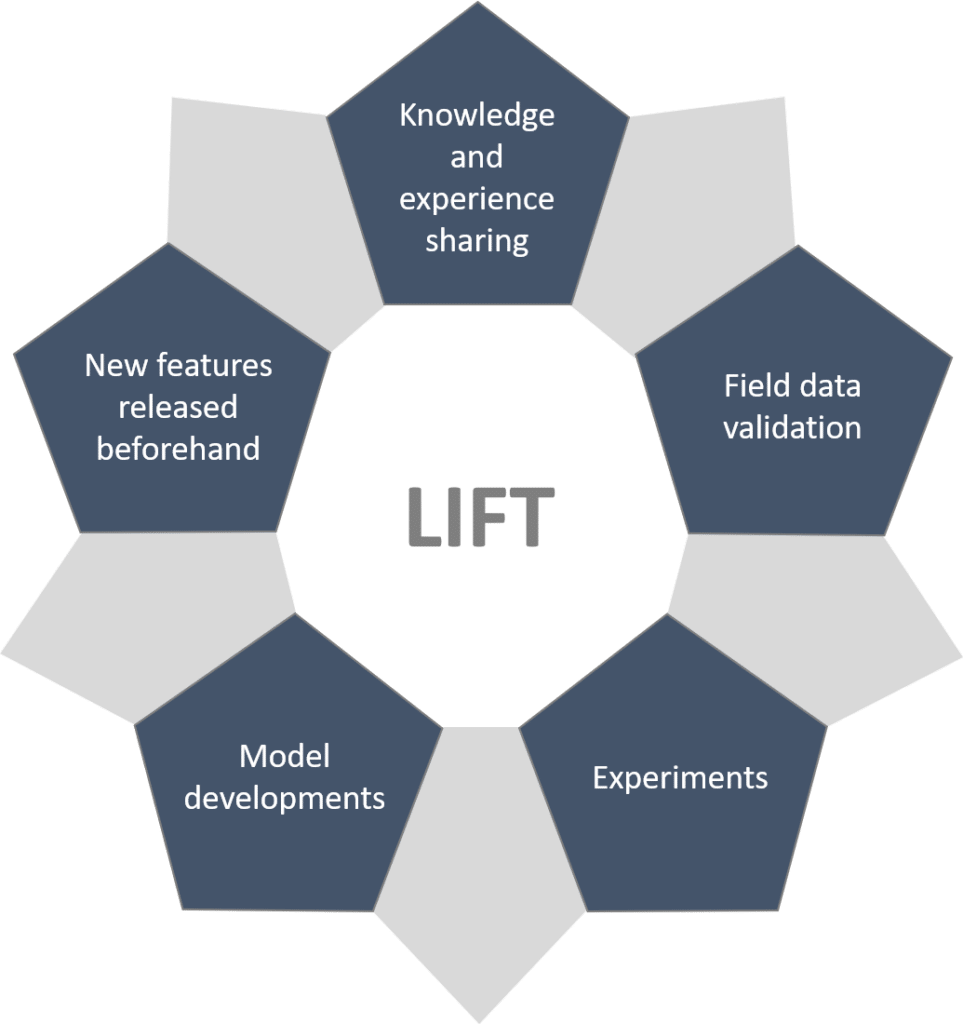

LedaFlow Improvements to Flow Technology (LIFT) is a joint industry project to identify areas for model improvement and ensure the industrial functionality and quality of LedaFlow.

Managed by KDI with support by SINTEF for experimentation and code improvements the project has entered its fourth phase (LIFT IV) with four operator partners: ConocoPhilips, Total, ExxonMobile and Woodside.

Participants

ConocoPhillips, ExxonMobil, TotalEnergies, Woodside

Project period

2024-2026

Participants

ConocoPhillips, ExxonMobil, AkerBP, TotalEnergies, Woodside

Project period

2021-2023

Participants

Chevron, ConocoPhillips, ENI, Lundin, TOTAL, Woodside

Project period

2016 – 2020

Participants

Chevron, ConocoPhillips, ExxonMobil, Shell, Statoil, TotalEnergies, Woodside

Project period

2013 – 2016

Fueled by BENZIN AS